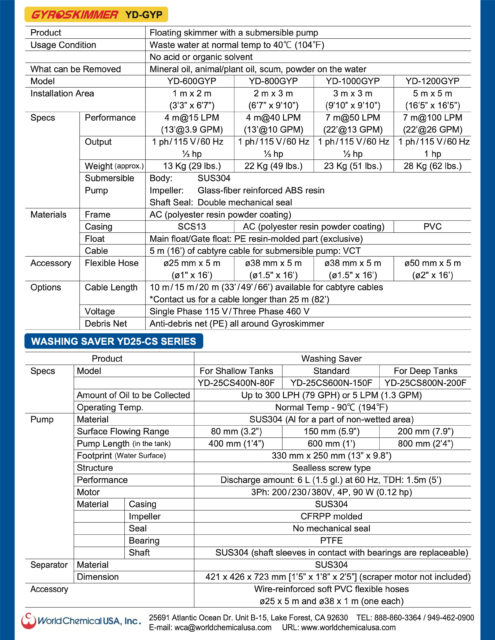

Free Estimate for your facility now

Highly-Efficient Skimmer for Various Industries such as Food Processing, Chemical, Automotive, etc. in Land and Water Applications

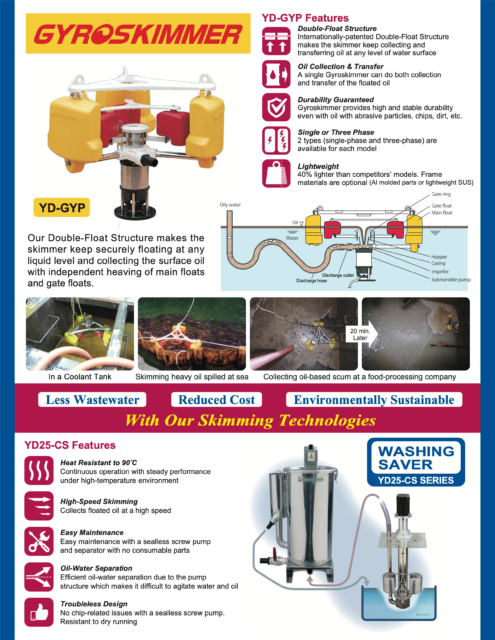

YD-GYP series is a floating scum skimmer designed for the collection of floating scum in wastewater treatment. It consists of a submersible pump and patented double floats and works in a sloshing condition.

Features

Patented Technology

The patented double float structure smoothly follows the swaying of waves and fluctuations in the liquid level, continuously sucking up and recovering surface oil.

Unique technology for efficiency

Floating pump skimmer collects and transfers oil steadily on the water surface with independent heaving of main floats and gate floats

The minimum necessary parts

No electric parts except the submersible pump. Equipped with an underwater pump, this single unit can collect and transport floating oil.

Weight saving

By matching aluminum molded parts with a lightweight SUS/resin pump, we have achieved a weight reduction of approximately 40% compared to conventional machines.

Other Features

- GYRO-SKIMMER is mainly composed of three large floats (Main floats), three small floats (Gate floats), a gate ring, a SCRAPER UNIT and a SUBMERSIBLE PUMP to collect floating oils on the water surface.

- Main floats having enough buoyancy follow the change of water level very well supporting the weight of a SCRAPER UNIT, a SUBMERSIBLE PUMP, a flexible hose and fittings.

- Gate floats ensure keeping a constant depth (height difference) of gate ring (oil collecting mouth) even on wavy surface.

- The skimmer collects oil steadily on the water surface because of the independent heaving of Main floats and Gate floats. The movement of Main floats gives almost no harmful influence to the height difference of gate ring.

- GATE RING has a screw thread to be adjustable to the thickness of collecting oil by turning itself.

- As a SCRAPER UNIT is mounted on the top of GATE RING, floating solids can be also scraped smoothly together with floating oils. Also, by the effect of SCRAPER UNIT, floating solids gathered around the GATE RING do not obstruct the flow of floating oil.

- SCRAPER UNIT is composed of a small reduction geared motor and a resinous scraper vane unit. The motor speed is approximately 4 rpm. 2-scraper vanes rotate always along the top of GATE RING and they can move also up and down. A switching power supply (24V DC) for control of geared motor attaches to the unit.

- Inner gears in the SCRAPER UNIT are hardly possible to be broken by locking of rotating axis, because of assembling a magnetic coupling.Furthermore, this design concept has also a sub-waterproof structure to protect the motor from a momentary submergence and a splash of water droplets. However, it is not applicable for submergence at deep water and for a long time, because the motor is not a full waterproof type. Do not use the SCRAPER UNIT in high humid environment such as in the dew.

- The skimmer collects oily water continuously in the SUCTION HOPPER by connecting a flexible hose to the pump and supplying power. The SUCTION HOPPER is molded together with the pump casing.

- The durable SUBMERSIBLE PUMP has a capacity of which can pump up smoothly solidified floating with oily water.

- Because the skimmer has no electric parts other than the SUBMERSIBLE PUMP and the SCRAPER UNIT, it is easy to handle and maintain such as cleaning.

- All of the main structural parts are manufactured based on original design. Therefore, their balanced arrangement displays an excellent performance

- Cable material : PVC / length: 32ft

Example to use

Chemical and Industrial Plants

Collecting and transferring floating oil in a coolant pit.

wastewater treatment plants

Collection and transfer of scum from wastewater treatment plants

Ponds, lakes & dams

Collection and transportation of aquatic plants, algae, and floating garbage.

Other uses

- For collecting and transferring floating oil in a coolant pit.

- For collecting and transferring floating oil with abrasion objects such as chips orslurry.

- For collecting and transferring scum in waste water plant.

- For collecting and transferring floating oil when cleaning contaminated soil.

- For collecting emergency spilled oil in river / port.

- For collecting floating oil on the spot of hard to heat retaining in cold climates.

- For collecting floating resin pellet or power

How to Installation

CASE STUDY

Free Estimate & Inquiry

Copyright © 2026 World Chemical USA, Inc. All rights reserved.