YD-NSF

Self-Priming Design with Open Impeller and Seal-less Structure

One of the toughest pumps in the industry. This self-priming pump never fails you even with slurries or dry running.

Features

- No troubles such as heat generation, wear, or liquid leakage with a seal-less structure

- Uses corrosion resistant resin (CFRPP). Can be used in a wide range of chemicals such as strong acid, alkaline solutions, etc.

- Less heat generation and wear due to dry running

- Long-lasting: resistant to waste liquid after surface plating

Reference

- Transferring/circulating pump for plating liquid to heat exchangers or filters

- Drawing/transferring pump for liquid from drainage pits or chemical liquid tanks

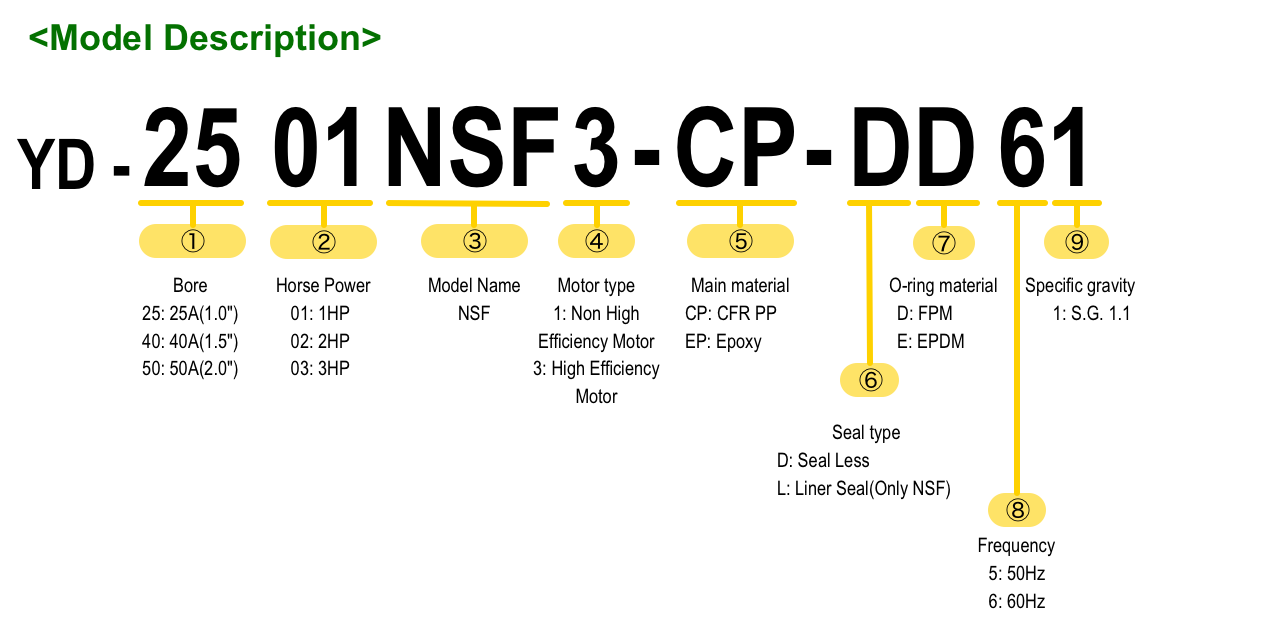

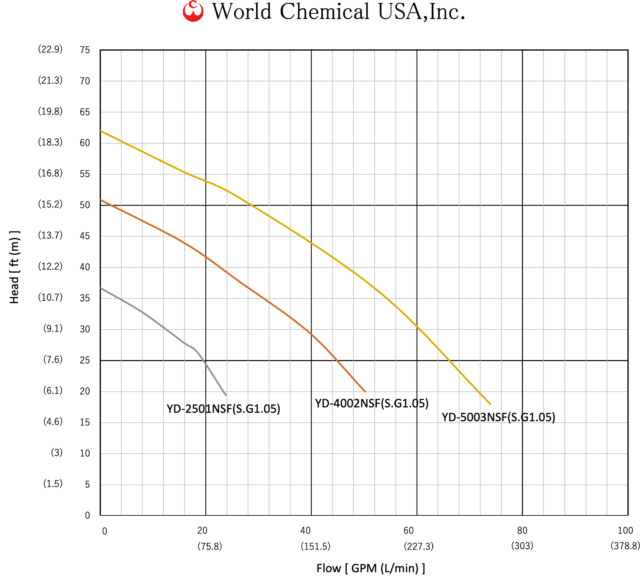

- YD-2501NSF

- YD-4002NSF

- YD-5003NSF

YD-2501NSF

Download Curve PDF

YD-4001NSF

Download Curve PDF

YD-4002NSF

Download Curve PDF

YD-5003NSF

Download Curve PDF

Applications

- Transferring/circulating pump for plating liquid to heat exchangers or filters

- Drawing/transferring pump for liquid from drainage pits or chemical liquid tanks

Video

YD-LRN

Pumps for Slurry Liquid Transfer

YD-LR pumps has NO sliding components in the structure and do not get damaged in circulating or transferring CPM slurry liquid, cerium oxide, etc.

Features

- Less than 1/10 of electricity cost compared to diaphragm pumps

- Lower maintenance cost as there are no consumable parts (ex. mechanical seals, gland packings, etc.)

- Resistant to abrasion due to slurries, dead-head operations, and dry running

- No sealings = no outer cooling water required

- Linear seals are protected with proximity sensors and PLCs

Reference

Applications

- Circulating CMP slurry liquid and cerium oxide

- Transferring “difficult” liquid such as:

- Crystallized liquid (acid, alkaline, solvent, etc.)

- Liquid with slurry