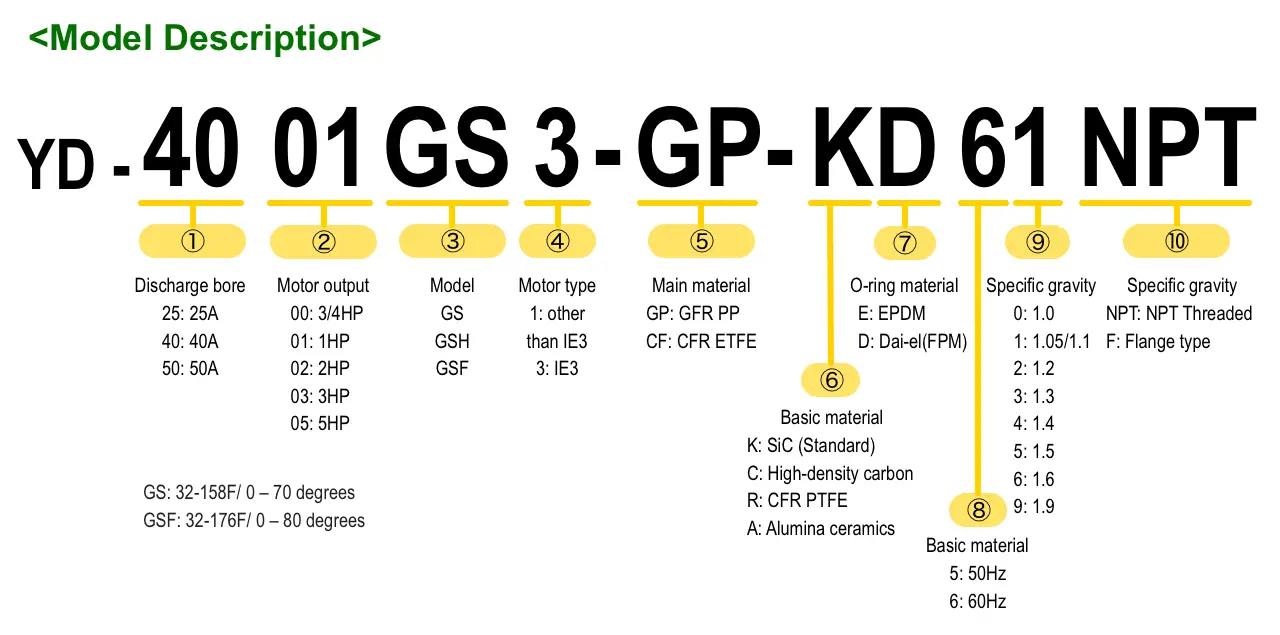

YD-2500/4000GS/GSF

Non-Metallic Magnetic Drive Pumps

YD-GS/F series are highly recommended for use in various production processes such as filtering, spraying, washing, plating, chemical transfer/blending, and etching in surface treatment applications

Features

- Polypropylene and carbon fiber reinforced Teflon

- JIS10K standard flange compatible with ANSI & DIN

- Easy to attach to NEMA-standard motors

- With neodymium magnets (2HP motor and above)

Reference

- Chemical Manufacturing

- Plating, Etching

- Metal Finishing

- Heat exchangers

- Chemical Blending

- Water Treatment

- Waste water treatment

- Paper Mill

- Fume Scrubbers

- Semiconductor

- Sodium Hypochlorite

- Generators

- Circulation

- Chillers

Polypropylene

- 2500GS=250GS

- 2501GS1= 251GS

- 2502GS1= 252GS

- 2503GS1= 253GS

- 4000GS (S.G.1.05) =400GS Flanged NEMA*Motor size can be varied

- 4001GS1 (S.G.1.1) = 401GS Threaded NEMA *Motor size can be varied

- 4001GS1 (S.G.1.1) = 401GS Flanged NEMA *Motor size can be varied

- 4002GS Threaded NEMA*Motor size can be varied

- 4002GS Flanged NEMA*Motor size can be varied

- 4003GS Threaded NEMA *Motor size can be varied

- 4003GS Flanged NEMA

*Motor size can be varied - 4005GS Threaded NEMA*Motor size can be varied

- 4005GS Flanged NEMA*Motor size can be varied

YD-2500GS-60

Download Curve PDF

YD-2500GS-63

Download Curve PDF

YD-2500GS-65

Download Curve PDF

YD-2501GS-60

Download Curve PDF

YD-2501GS-63

Download Curve PDF

YD-2501GS-65

Download Curve PDF

YD-2502GS-60

Download Curve PDF

YD-2502GS-63

Download Curve PDF

YD-2502GS-65

Download Curve PDF

YD-2503GS-61

Download Curve PDF

YD-2503GS-63

Download Curve PDF

YD-2503GS-65

Download Curve PDF

YD-4000GS-61

Download Curve PDF

YD-4000GS-61(0.75HP)

Download Curve PDF

YD-4000GS-63

Download Curve PDF

YD-4000GS-63(0.5HP)

Download Curve PDF

YD-4001GS-61

Download Curve PDF

YD-4001GS-63

Download Curve PDF

YD-4001GS-65

Download Curve PDF

YD-4002GS-61

Download Curve PDF

YD-4002GS-63

Download Curve PDF

YD-4002-65

Download Curve PDF

YD-4003GS-61

Download Curve PDF

YD-4003GS-63

Download Curve PDF

YD-4003GS-65

Download Curve PDF

YD-4005GS-61

Download Curve PDF

YD-4005GS-63

Download Curve PDF

YD-4005GS-65

Download Curve PDF

YD-4000GSF-61(0.5HP)

Download Curve PDF

YD-4000GSF-62(0.75HP)

Download Curve PDF

YD-4000GSF-65(0.75HP)

Download Curve PDF

YD-4001GSF-62

Download Curve PDF

YD-4001GSF-65

Download Curve PDF

YD-4001GSF-69

Download Curve PDF

YD-4002GSF-62

Download Curve PDF

YD-4002GSF-65

Download Curve PDF

YD-4002GSF-69

Download Curve PDF

YD-4003GSF-62

Download Curve PDF

YD-4003GSF-65

Download Curve PDF

YD-4003GSF-69

Download Curve PDF

YD-4005GSF-62

Download Curve PDF

YD-4005GSF-65

Download Curve PDF

YD-4005GSF-69

Download Curve PDF